Digital printing

Description

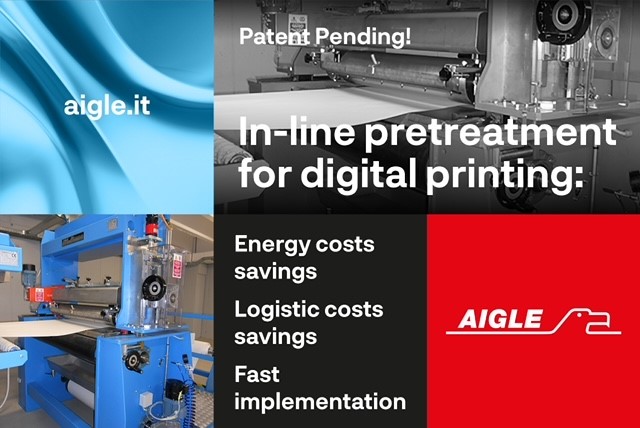

Aigle Macchine Srl has developed and patented a system for pre-treating incoming fabrics of digital printing lines.

The system consists in doctor-blade coating a chemical product (compound for printing with acids or reactive) on a fabric to improve the printing carried out in a digital machine (plotter, discontinuous and continuous feed). The fabric is then pre-dried, calendered and fed onto an adhesive conveyor belt of a digital printing line. The fabric can be pre-dried on the reverse side. For this purpose, there is a heater close to the 'light' squeezing calender to be carried out after coating. The coating system for digital printing fabric pre-treatment is also equipped with a synchronizing unit suitable to compensate the continuous or discontinuous coating feed with the web feed of the printing machine.

Machine is suitable for:

Full cover coating over cylinder

Full cover coating by floating blade

Strengths new pre-treatment bench for digital printing mod. bsr-dig

1) ability to print wet-on-wet for better colour penetration.

2) possibility of increasing or decreasing the degree of wetting of the fabric before printing

3) can be used with all types of colour (acids, reactive pigments)

4) impregnation step with stenter frame oven is avoided

- less use of manpower

- less energy use for the line with stenter frame oven

- less waste of chemistry at the end of processing when washing out the residual unused chemistry

5) sustainability.

- less use of water in the case of use of shelter (reagents).

- less use of space for storage of pre-treated pieces waiting to be processed with risk of yellowing and necessary cleaning and reprocessing treatment in case of prolonged shelf waiting.

6) cost-effectiveness:

50 cents (euro) machine passage

- 12 cents raw materials

- 8 miscellaneous expenses squeegee treatment

= savings of about 30 cents per square meter

with a production of 2000 square meters per day = about 130,000 euros per year. payback in about 1.5 years.

7) possibility of making immediate prints without the wait for pre-treatment in the stenter frame oven

8) ability to process all fabrics even the most complex ones like wool and silk.

Address

Aigle Macchine S.r.l.

Via Donatello 8

10071 Borgaro Torinese Torino

Italy

Telephone+39 011 262 4382

Fax+39 011 262 4348

Discover more from us