Poly-clip System GmbH & Co. KG

Adresse

Poly-clip System GmbH & Co. KG

Niedeckerstr. 1

65795 Hattersheim am Main

Germany

Telefon+49 6190 88860

Entdecken Sie mehr von uns

Über uns

Poly-clip System is the largest provider of clip closure systems worldwide and is recognised as world market leader and hidden champion in this sector of the food industry and packaging industry. The history of the German family firm, based in Hattersheim near Frankfurt am Main, stretches back as far as 1922. To date we own more than 1000 patents, a fact which underlines our global technology leadership. With an export rate of almost 90% our clip closure solutions are in use around the world. Excellence in Clipping The highest quality and reliability combined with outstanding service – that is exactly what both the customer and we ourselves are aiming for. From now on we want to be your ideal partner in all aspects of clipping – with our unique product and service system. Adapting to your needs, and focusing on your benefit, we will provide you with efficient and innovative solutions, from manual table top machines through automatic double-clippers to automated systems for smoke trolley loading, not forgetting consumables such as clips and loops. Our constant challenge in everything we do is, and will continue to be, to offer our customers ‘Excellence in Clipping’.

Everyone is familiar with the ends of a sausage, the ‘tails’. Originally developed by us for the meat processing industry and the butchery trade, our clip closure system has long been successfully employed in other food and non-food areas. Packaging with the clip is efficient, safe and permanent. The clip accounts for only 1% of the cost of a product, but can determine more than 100% of its success. We are suppliers to the meat industry as well as the growing sector of plant-based and alternative proteins. We can also account among our customers the dairy industry and manufacturers of convenience products, bakery, confectionery products and pet foods. Poultry, fruit and vegetables are also securely packaged in bags or nets with clip closure. Through our network of exclusive distribution partners in over 145 countries you will be able to receive professional advice around the world – we are there for you. Supported as we are by this network, you can have complete confidence in our fully qualified service organisation wherever you are in the world. Excellent support, flexibility and a willingness to help are our trademark. After all, it’s only your satisfaction that counts! Benefit from our know-how and experience – trust in Poly-clip System.

Mehr über uns

Special Interests

Unsere Marken

clip-pak®

Keywords

- Aufhängelinie

- Doppelclipper

- Wurstclipper

- Clipping Hanging Machine

- Double-Clipper

Unsere Produkte

FCA 160 | Automatic Double-Clipper

- No one else has it: Automatic adjustment of clip pressure and displacer

- No one else has it: Automatic monitoring of clip, die and punch (RFID)

- No one else has it: Automatic central lubrication

- No one else has it: Automatic adjustment of filler and clipper

- No one else has it: Double clip monitoring

- No one else has it: Casing break monitoring

TSCA 65 D | Automatic Sealing/Clipping Machine

- No one else has it: Automatic adjustment of clip pressure and displacer

- No one else has it: Automatic monitoring of clip and die (RFID)

- Measuring out device can be integrated

- Solvent sealed packaging

- Simple and safe marking of batches during production by continuous printing on flat film using an integral printer, e.g. ink jet, hot stamping, thermal transfer

APL | Automatic Poultry Loader

- Automatic packaging of poultry in bags for reduced man- power

- Processes bags from a wicket

- Up to 18 bags per minute

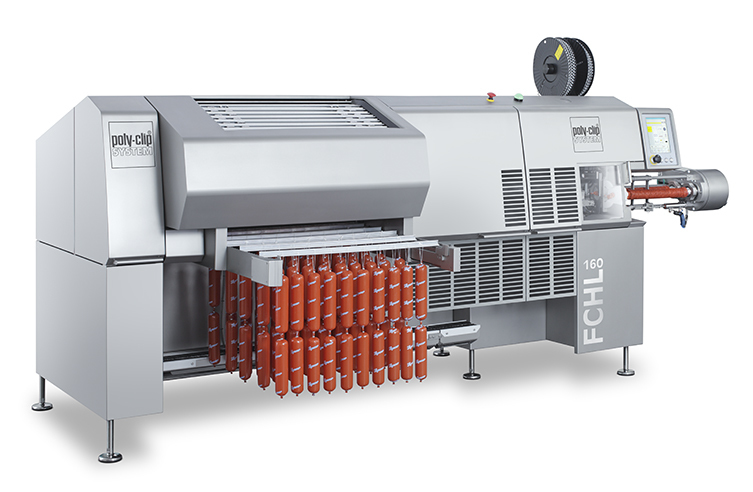

FCHL | Automatic Clipping/Hanging Machine

FCHL

Working continuously as in Europe's most modern production site

Up to 25% productivity increase and up to 37% manpower saving

This is what makes it unique: the new Automatic Clipping/Hanging Machine from Poly-clip System combines four production processes in a single machine. In this way it offers a cost saving of up to 37% on manpower while at the same time increasing output by up to 25%.

All-in-one Automatic Machine

This automatic clipping/hanging machine FCHL efficiently combines clipping with simultaneous looping and automatic hanging and positioning of products on the smoke stick. Its high level of automation ensures continuous, reliable production at a positioning rate of up to 85 loop per minute (depending on calibre and process). The automatic clipping/hanging machine thus benefits from all of the advantages of the tried-and-tested FCA 160/120 double-clipper. Continuous, precise positioning on the smoke sticks in the hanging unit permits a higher loading density and thus optimum utilisation of smoking and cooking plant capacity. Compared with the use of a conventional filling line, e.g. comprising an FCA 3430 and filler operating in 2 shifts (8 operators), a productivity increase of up to 25% is achieved with 37% less manpower.

What marks the FCHL out?

This automatic machine has state-of-the-art PC control, which permits simple operation from a single SAFETY TOUCH and provides rapid, smooth start-up after coupling to the filler. Casing re-load occurs while the clip head is stationary. Product parameters are of course retrievable from recipe management, and PC control offers rapid and precise signal processing. Thanks to the intelligent drive control unit, extremely precise loop positioning with product settling results in more products on the smoke stick, and thus in a higher output.

Productivity increases further with the ASL-R

The output rate increase totals 40% when the Automatic Sausage Loader ASL-R takes over loading of the smoke trolleys. At the same time, the manpower requirement can be reduced to 3 operators in 2-shift operation, which corresponds to a total saving of 60 % on operating staff. This increase in efficiency is made possible by the ASL-R, a fully-automatic robot-controlled machine for discharging smoke sticks and loading them into smoke trolleys – the robot does not require work breaks and never suffers from any illness. The ASL-R brings the output to 6 smoke sticks per minute, which it automatically positions in the smoke trolley with great precision. The innovative automatic clipping/hanging machine FCHL turns out products in the calibre range from 38 to 100 mm and processes metal or plastic smoke sticks which are suitable for automation (800 to 1,250 mm).

As usual, Poly-clip System offers the highest processing quality and a robust hygienic design. The machine’s compact construction and powerful servo drive are designed for continuous operation. Central lubrication keeps wear and tear to a minimum, and easy access to the machine for the purposes of maintenance and thorough cleaning is afforded by large maintenance flaps and by means of a special cleaning position of the clip head.

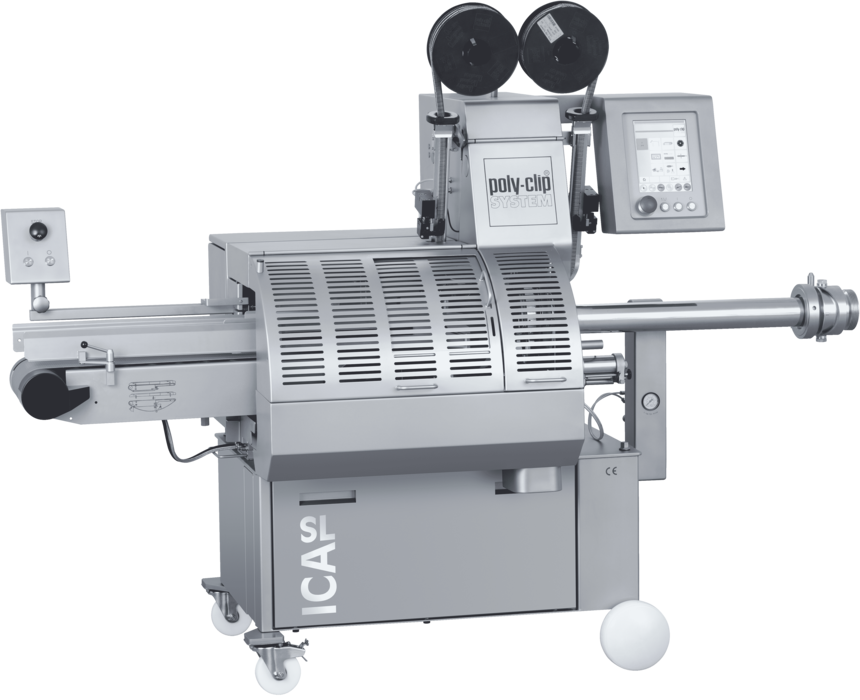

ICA SL | Automatic Double-Clipper

- No one else has it: Automatically generated self-locking loop, suspension up to 16 kg

- No one else has it: Swivel brake for perfect sausage pattern

- No one else has it: Robust iris displacer up to caliber 200 mm

- Specialist machine for heavy products whichundergo further processing while hanging on a loop

- Calibre rangefrom 60 to 200 mm

- Up to 30 cycles per minute in continuous mode

- Innovative iris separator for short, symmetrical sausage shoulders